When it comes to real-life examples of the expression “good things come in small packages,” it is hard to beat the o-ring. This compact solid rubber seal is one of the most widely used, reliable and sturdy sealing solutions in the world. While o-rings are small in stature, they can literally be difference between huge pieces of equipment working properly or breaking down.

And although the basic shape of the o-ring has not changed over the years, the sealing technology behind it has. To get to know this small but mighty seal a bit better, let’s start by looking at its history as well as recent developments in o-ring design and more.

1937: The Year the O-Ring Was Born

As The Inventors notes, Niels Christensen invented the o-ring in 1937 when he was developing brakes for automobiles. He received a patent for his invention and during World War II was able to sell the o-rings to the military for use on their aircraft. By the 1950s, o-rings were routinely used in everything from cars and plumbing to appliances, farm equipment, valves and many other devices. Today, o-rings are used in numerous applications across land, sea, in air and in outer space.

All O-Rings Are Not Created Equally

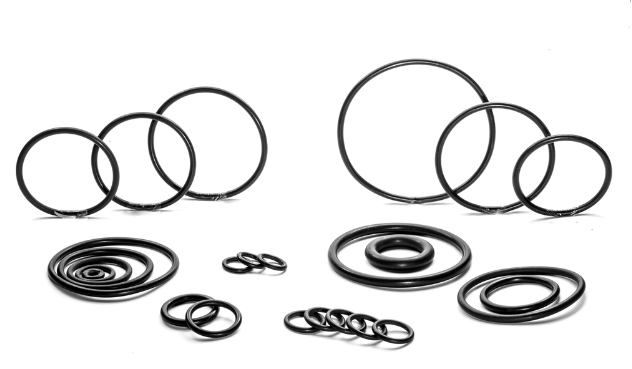

While an o-ring in its most simplistic form is a circular rubber seal, over time a wide range of seals have been created from different types of polymer materials. According to The Citizen Journal, researchers have paid close attention to the o-rings and how they are used, and have continually been on the lookout for ways to improve their performance. For example, if an o-ring is used in equipment with a high-pressure bearing capacity, the material used to create the o-ring must be able to withstand this condition. On the other hand, o-rings that are used to create a tight seal in an automotive system may be made from a different material. Rather than mere rubber, o-rings are now made from a different combination of chemical ingredients, including polymers/elastomers, curing agents, plasticizers, flame retardants and inert or carbon fillers.

O-Rings Now Seal Better Than Ever

While the o-ring is still as round as the day Niels Christensen invented it, the engineering tools used to create this vital seal have improved over the decades. Today, PC-based software packages are available that will enable companies to create the most reliable and sturdy o-rings ever. O-rings are available in a wide range of sizes and hardness ratings; for example, Apple Rubber offers AS568 and ISO 3601 standard sizes with a hardness range from 10 to 90 Shore A durometer, as well as 8,000 different non-standard sizes. They also feature MicroOrings which, as their name implies, are incredibly tiny — they are for inner diameters less than 0.036″ or 1 millimeter.

Advancements Have Led to a Proliferation of Uses

As o-rings have been improved upon, in their materials, sizes and how they are produced, they have become more prevalent than ever. Virtually every industry uses o-rings in some capacity, including jewelers, plumbers, refrigeration and air conditioning technicians, and people in the medical field who use syringes and other devices. Basically, if a product requires some type of seal, an o-ring is ready and able to do the job.

What’s Next? Time Will Tell

If Niels Christensen were alive today, he would probably be both amazed and impressed at how far his round seal has evolved. Although it is still used in both cars and airplanes, the advancements in o-ring materials and technology mean that this diminutive seal is a key and vital component in thousands of other products.